FREQUENTLY ASKED QUESTIONS

Label Services

Yes! Our HP Indigo Digital Presses are able to reduce the impact of printing on the environment. These presses were manufactured “CO2 neutral” and designed with reusable and recyclable parts. Labelworks complies with strict EPA and FDA regulations during the printing process whether it be Toner based, Inkjet based or Flexo based production.

FILE FORMAT:

– High resolution print ready Adobe Illustrator PDF files with fonts converted to outlines, images and TIFFs embedded.

– Please be sure all corners have 1/8” radius. (.125”)

COLOR:

– Converting RGB files causes significant color shifting.

– Avoid this by creating files using CMYK color only.

– Supplying a color target or sample whenever possible.

– Avoid trapping ( trapping will need to be removed) 7 color process is available, CMYKOV available at an additional charge.

– Please supply any PMS colors or send us swatches to match to.

PRINTING ON CLEAR / METALLIZED MATERIALS:

– If artwork is going to be on clear material IT NEEDS TO BE INDICATED IN YOUR ARTWORK.

– You may use a spot color and rename it “white” in the file to show where the color white is printed and where the material will be knocked out / shown through.

– Please add the color “White” to the file title as well.

FONTS:

– Only Postscript & Open type fonts are accepted.

– Minimum font size for dark text on light backgrounds is 3pt

– Minimum font size for white on colored background is 3pt BOLD.

– All fonts must be included with job in both screen and print faces.

We prefer that our customers supply their own print ready artwork, however, we do have graphic designers on staff that would be happy to assist you.

Yes! We have a variety of special dies in house and can custom order almost any die-cut shape.

There is a $500 minimum on all orders. Your order can be adjusted by size, quantity, and material to get the most out of this requirement.

Some factors to consider before matching your product with the most fitting label material:

- Surface on which your label will be applied to (glass, metal, plastic…)

- Strength of the adhesive required

- Temperature sensitivity

- Water resistancy

Please note that changes, modifications, or corrections that need to be made after the proofing process can result in extra charges and delays in processing your order.

Yes! Add-on components and accessories are available to suit your high speed systems.

These add-on components allow for diverse applications.

PLACED IMAGES:

– All image should be at least 300dpi (Photoshop does not vector, any type in photoshop will print blurry)

– Images should be in CMYK format

– All images must be embedded or you must provide all fonts and all images.

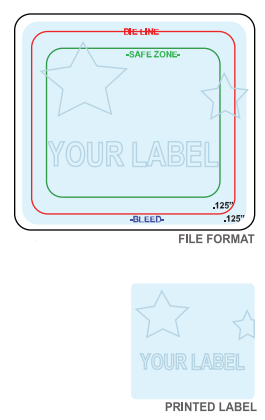

BLEED:

– We require files to be prepared with full bleed. Bleed means your label artwork extends beyond the actual finished dimentions of your label, allowing the printer a small amount of space to account for movement of paper or design nconsistencies. To do this simply make images and graphics ‘Bleed’ past the Die Line an additional 1/8” (.125”)

DIE LINE (where the artwork gets cut):

– This line does not print and is the actual size of your label.

– Die Line should be indicated as “spot color Die Line” or “swatch Die Line” in title case

SAFE ZONE:

– Important artwork/ text that you do not want cut off must be within the Safe Zone (at least .125” away from the Die Line)

PRESS PROOFS:

– Available prior to production run. Prices vary depending on the number of copies.

(Not Limited to) COMMONLY USED MATERIALS:

1. WHITE

– BOPP (Polypropylene Film) – This is water and oil resistant Biaxially Oriented Polypropylene with permanent adhesive. Suitable for bath and body products, as well as food and beverage products.

– Gloss paper

– Matte paper

– PET (Polyester)

– Squeezable Film – Commonly used for tube labels, shampoo bottles, ets.

2. CLEAR

– Clear BOPP Clear – Water and oil resistant. Provides a “no-label” look.

– PET

– Clear Squeezable

3. METALLIZED

– MET. BOPP – Water and oil resistant. Provides a “mirror-like” shine of chrome.

– MET. PET

– MET. Paper

– MET. PET Holographic (Rainbow)

4. SPECIALTY

– Wine Label Stocks

– Natural Kraft

– Recycled Material

5. COATINGS & LAMINATIONS

– Gloss

– Semi-Gloss

– Matte

To reproduce full-color images, typical printing processes uses four colors of ink. The four inks are placed on the label in layers of dots that combine to create the illusion of many more colors. CMYK refers to the four ink colors used by the printing press. C is cyan, M is magenta, Y is yellow and K is black.

Spot colors are any solid colors called out in the printing process. They can be Pantone, CMYK values, LAB values, or hexadecimal colors

Yes, we can. All of your labels will be quoted and printed as a four-color process (CMYK). If you have a special color to match, please let us know. We can match Pantone colors to a high degree of accuracy with our state-of-the-art digital printing presses.

There is a $25 Art Work Prep fee.

Absolutely. If you have several label versions of the same size, shape, material and finish, you can combine them all into one, larger order. Increasing your order size in this fashion will actually reduce your per-label costs. Simply let us know how many design versions you have and send us the artwork files for each.

Yes, there is a difference in pricing depending on if you print in color or black and white. Please reach out to our customer service team for more infomation.

To reorder labels, simply call (215) 945-5645 or email labels@labelworx.net and one of our customer service representatives will be happy to assist you.

We ship all label via standard UPS Ground or FedEx Ground unless otherwise noted. You have the option to upgrade to ship overnight or two-day shipping for an additional fee. Additionally we have courier services and do have pickup hours for customers that are local.

Frequently asked questions

Labeling Machinery

Yes! We understand the importance of time efficient precision and superior quality.

Aside from system parts, we also offer maintenance and repair services to continue to ensure your machinery is operating at full capacity.

Yes! Labelworx, an Inovar company is the #1 leading distributor for HERMA labeling systems in the USA. Additionally, Labelworx, an Inovar company is a certified distributor / service provider for CTM and EAM labeling systems as well as SATO, ZEBRA, and Datamax by Honeywell thermal printers and print engines.

Yes & Yes! We sell a variety of ribbons and labels in different sizes and colors. Simply fill out our ‘Contact Form’ or email us directly at machinery@labelworx.net and a member of our team will be in touch!

If the parts are in stock at our facility, we can typically ship within 24-48

hours. However, custom parts typically have an extended lead time. We

suggest requesting a quotation and lead time prior to placing your order so

that we can provide you with current information.

Labelworx, an Inovar company does not have any minimum order requirement for any parts

that are kept in stock at our facility, however some of our suppliers require

a minimum order for parts and consumables. Please reach out to our

support team at machinery@labelworx.net for questions regarding a

specific part number.

Yes, if the parts and/or consumables are not stocked at our facility, we can

request that they are drop shipped directly to you from our suppliers.

There may be a small fee associated with this, therefore we suggest

requesting a quotation prior so we can provide you with current

information.

Please email our support team at machinery@labelworx.net to schedule a

service appointment. Additionally, please provide us with the machine

make, model, serial number, and a brief description of the repair needed.

Please reach out to our sales team at machinery@labelworx.net or call

215-945-5645 for all quotations. Our office is open M-F from 8am-4pm.

Machinery repairs depend on the scope of work needed and if the parts

are in stock. We make every effort to provide a quick turnaround for all

repairs.

Yes, Labelworx, an Inovar company offers a (1) year limited warranty. Please reach out to our

support team for further details.

For new customers, we require payment via credit card for the first order.

After your first order, we can extend Net 30 terms (pending approval from

our Accounting Department).

Any Questions

-

Phone

(215) 945-5645 -

Email

Label Services: labels@labelworx.net

Label Machinery: machinery@labelworx.net